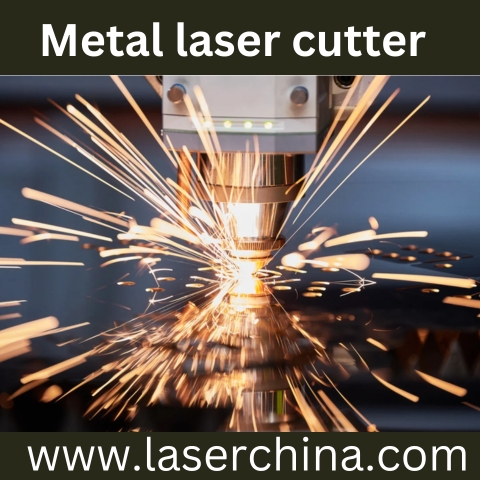

Laser cutting has revolutionized the metal fabrication industry, and LaserChina stands at the forefront with its advanced metal laser cutter technology. From aerospace components to customized signage, these machines offer unmatched speed, accuracy, and versatility. In this in-depth guide, we explore how LaserChina’s metal laser cutters transform industrial production, why they lead the market, and what makes them a trusted name in global manufacturing.

What is a Metal Laser Cutter?

A metal laser cutter is a high-precision machine that uses a focused laser beam to cut through metals such as steel, aluminum, brass, and copper. LaserChina’s systems use fiber laser technology, delivering clean edges, minimal material waste, and reduced operational costs.

Why LaserChina? Key Differentiators

LaserChina is a recognized expert in laser solutions with over 20 years of R&D and manufacturing experience. Here’s what sets them apart:

Industry-Proven Expertise

-

100,000+ machines installed worldwide

-

20+ patents in laser technology

-

ISO and CE certifications ensure product compliance

Broad Product Range

-

Fiber laser cutters (1kW to 30kW)

-

CO₂ and UV laser models

-

Handheld, desktop, and industrial-scale solutions

After-Sales & Global Support

-

24/7 technical assistance

-

Multilingual customer support

-

Training and maintenance programs for every purchase

LaserChina’s Metal Laser Cutter Specifications at a Glance

| Feature | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Power Range | 1kW to 30kW |

| Supported Metals | Stainless steel, carbon steel, aluminum, brass |

| Cutting Thickness | Up to 60 mm (material-dependent) |

| Cutting Speed | Up to 120 m/min |

| Software Compatibility | AutoCAD, CorelDRAW, SolidWorks, AI |

| Cooling System | Water-cooled integrated system |

| Precision Tolerance | ±0.02 mm |

How Does LaserChina Ensure Cutting Edge Performance?

LaserChina’s core strength lies in three critical pillars:

1. Advanced Beam Quality

LaserChina uses IPG and Raycus sources with ultra-stable wavelengths, allowing consistent beam intensity for superior metal cutting.

2. Robust Structural Engineering

Heavy-duty bed design absorbs vibrations, improving precision and tool longevity even at high speeds.

3. Smart Control Systems

AI-assisted motion control and real-time monitoring software reduce errors, automate processes, and provide predictive maintenance alerts.

Benefits of Choosing a LaserChina Metal Laser Cutter

-

Faster Turnaround Times

Cut production time by up to 70% with high-speed operations. -

Unparalleled Accuracy

Achieve micro-level detail even in intricate patterns or thin gauge materials. -

Energy Efficiency

Fiber laser technology uses less power than traditional CNC methods. -

Low Maintenance Costs

With fewer moving parts and sealed laser sources, downtime is minimal.

FAQs: Everything You Need to Know

What metals can LaserChina cutters handle?

LaserChina’s machines work with stainless steel, mild steel, galvanized steel, aluminum, copper, titanium, and more.

Can a beginner operate these machines?

Yes. The intuitive user interface and comprehensive training offered by LaserChina make it beginner-friendly without sacrificing industrial capability.

How long do the laser sources last?

Fiber laser sources generally last between 80,000 to 100,000 hours of operation with minimal performance degradation.

Are customizations available?

LaserChina offers modular designs. Customers can request custom bed sizes, power ranges, automation add-ons, and software integrations.

What industries use LaserChina cutters?

-

Automotive

-

Aerospace

-

Electronics

-

Medical device manufacturing

-

Construction and architecture

Practical Tips for Maximizing Performance

-

Use the correct lens for each material thickness.

-

Keep the nozzle clean to maintain consistent beam quality.

-

Calibrate software regularly for dimensional accuracy.

-

Schedule preventive maintenance every 500 operational hours.

Final Thought

With a powerful mix of cutting-edge technology, proven reliability, and user-centric design, LaserChina’s metal laser cutter solutions are ideal for businesses looking to optimize performance and precision in metalworking. Whether you’re scaling production or enhancing custom prototyping, their machines provide a competitive advantage that’s hard to match.